Picking a Manufacturer to Build Your Control Panels

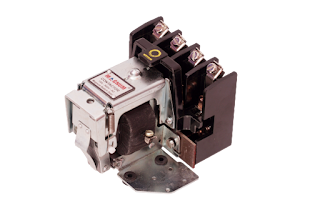

An engine magnet starter is a progression of contacts set off by an electromagnetic starter to begin and stop the related engine load. A control circuit, in which a temporary contact gadget is associated with an attractive starter circuit, plays out the errand of beginning and halting. The accompanying instrument shapes a three-post voltage with an attractive starter: • Set lasting contacts • various non-lasting contacts • pressure springs • solenoids • Stationary electromagnets • Set attractive concealing circuit • Detachable installation The attractive starter is a full voltage starter that offers warm over-burden and quick assurance for the authority confine engine. This can be controlled consequently or distantly with the press of a catch when you are not before the machine. The objective is that the motor isn't excessively hot. The right proportion of the heap on the engine is the current depleted from the engine. Because